OEM High Precision CNC Machining Parts Service

CNC Machining Service

▪ Njira: Kutembenuza kwa CNC, Kugaya CNC, Turn-mphero Compound.

▪ One-Stop Solution Kuti CNC Machining.

▪ Zida Zamakina za OEM, Zigawo Zoponyera, Zigawo Zopangidwa ndi Makina, Zigawo Zachikhalidwe za CNC, Ma Prototypes.

▪ Wopanga Zinthu Zolondola Kwambiri.

▪ Wopereka Machining CNC Wapamwamba.

▪ Kusintha Mwamakonda Anu: Logo yosinthidwa mwamakonda anu, kuyika mwamakonda anu, makonda azithunzi.

▪ Zida: Chitsulo chosapanga dzimbiri, Aluminium, Carbon steel, Copper, Brass, Steel Alloy, Titanium etc.

| Zapamwamba Zolondola Zapamwamba za OEM CNC Machining Part | |

| Utumiki | Kutembenuza kwa CNC, CNC Milling, Laser kudula, kupindika, kupindika, kudula waya, kupondaponda, Kutulutsa Magetsi (EDM), Kupanga jekeseni |

| Zipangizo | Aluminiyamu: 2000 mndandanda, 6000 mndandanda, 7075, 5052, etc. |

| Chitsulo chosapanga dzimbiri: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | |

| Chitsulo: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | |

| Mkuwa: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | |

| Titaniyamu: Gawo F1-F5 | |

| Chithandizo cha Pamwamba | Anodize, Bead kuphulika, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| Kulekerera | +/- 0.002 ~+/-0.005mm |

| Kukalipa Pamwamba | Mphindi Ra0.1 ~ 3.2 |

| Kujambula Kuvomerezedwa | Stp, Step, Igs, Xt, AutoCAD(DXF, DWG), PDF, kapena Zitsanzo |

| Nthawi yotsogolera | Masabata 1-2 a zitsanzo, masabata 3-4 opangira misa |

| Chitsimikizo chadongosolo | ISO9001:2015, ISO13485:2016, SGS, RoHs, TUV |

| Malipiro Terms | TT / PayPal / WestUnion |

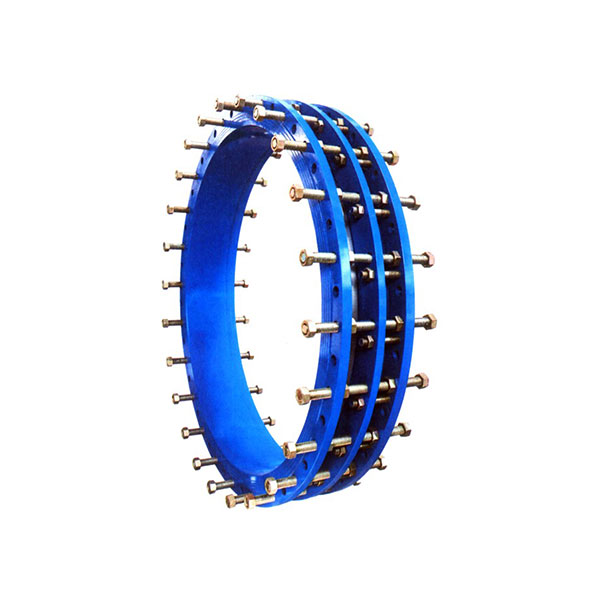

OEM CNC Machining High Precision High Quality Steel / Zigawo Zachitsulo

OEM CNC Machining High Quality Brass ndi Titanium Parts

Kupaka Kwazinthu

FAQ

1. Kodi CNC Machining ndi chiyani?

CNC (Computer Numerical Control) ndi mtundu wa kupanga subtractive.Kutengera zojambulazo, CNC imagwiritsa ntchito zida zosiyanasiyana kudula zopangira ndi mapulogalamu.

2. Kodi gawo langa lingapindule bwanji ndi CNC?

Poyerekeza ndi njira zina kupanga, CNC Machining ndi njira zosunthika kwa zipangizo, miyeso, otsika-mkulu voliyumu kupanga.Zimatsimikizira kukhazikika, kulondola, ndi kulolerana kolimba.

3. Ndingapeze bwanji mawu?

Zojambula zatsatanetsatane (PDF/ STEP/IGS/DWG...) zokhala ndi zinthu, kuchuluka kwake komanso chidziwitso chamankhwala apamwamba.

4. Kodi ndingapezeko mawu opanda zojambula?

Zedi, tikuyamikira kulandira zitsanzo zanu, zithunzi kapena zojambula zokhala ndi miyeso yatsatanetsatane kuti mutenge mawu olondola.

5. Kodi zithunzi zanga zidzawululidwa ngati mupindula?

Ayi, timasamala kwambiri kuteteza zinsinsi za makasitomala athu pazojambula, kusaina NDA kumavomerezedwanso ngati pakufunika.

6. Kodi mungapereke zitsanzo musanapange misa?

Zowonadi, chindapusa chachitsanzo chikufunika, chibwezeredwa pakapanga misa ngati nkotheka.

7. Nanga bwanji nthawi yotsogolera?

Nthawi zambiri, masabata 1-2 a zitsanzo, masabata 3-4 opangira misa.

8. Kodi mumayendetsa bwanji khalidweli?

(1) Kuyang'ana kwazinthu--Yang'anani zakuthupi ndi kukula kwake.

(2) Kuwunika koyamba kopanga--Kuwonetsetsa kuti pakufunika kwambiri kupanga zambiri.

(3) Kuwunika kwa zitsanzo--Yang'anani ubwino musanatumize ku nyumba yosungiramo katundu.

(4) Kuyendera kusanachitike--100% kuyesedwa ndi othandizira a QC asanatumize.

9. Kodi mungatani ngati titalandira zigawo zosaoneka bwino?

Chonde titumizireni zithunzizo, mainjiniya athu apeza mayankho ndikukupangiraninso mwachangu.